xtronix stocks:

Download this PDF on

diffusion pump technology

![]()

xtronix caters to a variety of vacuum and non-vacuum applications with different grades of Krytox® oils and greases. We have addressed aerospace related markets, high voltage industrial applications, paper mills, tribology applications in clean room environments, and many others.

An important area of use for Krytox® relates to vacuum-based applications:

Krytox® performance lubricants for vacuum systems are reliable, cost-effective, and safe in all environments. Even in the most chemically severe environments, Krytox® oils and greases are:

Krytox® Oils and Greases offer a unique combination of properties that provide exceptional, yet cost-effective solutions to your most difficult lubrication problems. Compared to other lubricants, only Krytox® Oils and Greases combine high-temperature performance, non-flammability, and chemical inertness under a variety of conditions. Krytox® Oils and Greases increase the service life of critical components, allowing equipment manufactures to extend warranties, and manufacturing plants to reduce costly maintenance due to component failure. Krytox® Oils and Greases are exceptional lubricants that provide superior protection and load-carrying ability under the most severe conditions. They are especially suited for use in 100% liquid or gaseous oxygen services.

A special low-vapour-pressure Krytox® oil is used to formulate a grease for high-vacuum applications. Krytox® greases are an excellent choice for lubricants or sealants used in all vacuum environments, especially when access for repair or replacement is difficult or impossible.

Low vapor pressure greases offer:

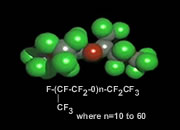

Krytox® is a PerFluoroPolyEther (PFPE)--also called PerFluoroAlkylEther (PFAE) or PerFluoroPolyAlkylEther (PFPAE). Krytox® fluorinated oils are a series of low molecular weight, fluorine end-capped, homopolymers of hexafluoropropylene epoxide.

Krytox® oils' unique properties are derived from its fluorinated structure. This structure, polyhexafluoropropylene oxide, is an extraordinary fluorinated ether and yields a highly lubricious liquid with extremely low volatility. This polymer is represented in the graphic below. It consists of a carbon (gray) and oxygen (red) ether backbone. This provides a flexible platform onto which the fluorines (green) are attached. The fluorine is responsible for providing the thermal and chemical stability ideal for use in severe environments. Krytox® oil is insoluble in water, acids, bases, and all common organic solvents and is nontoxic.

Krytox® 1500 Vacuum Pump Fluids are also available with antirust protection. The fluids are called 1506XP, 1514XP, 1525XP and 1531XP. They have all of the same properties of the standard fluids listed in the PDF below. Krytox® XP oils contain a soluble additive to prevent rust. This new patented additive enhances the performance of Krytox® VPF fluids, giving them improved performance properties. The long-term antirust properties repel moisture, providing extra protection from corrosion of metal parts and bearing surfaces.

While Krytox® VPF fluids are inert and nonreactive to all elastomers, plastics, and metals, the soluble additives in the XP products are new and have not been tested with all materials. It is possible that some reactivity and damage could occur to some materials. Initial testing has shown no problems with Teflon®, Kalrex®, Viton®, nitrile, and silicone rubbers. There is some reactivity of the additive with copper, but it is less with brass. These additives could have degradation of performance at elevated temperatures over 175°C (347°F) over a long period of time.

Download datasheet for 1500 & 1600 fluids

![]()

Krytox® LVP High-Vacuum Grease

*

Download

datasheet for LVP grease

DuPont does not

make any express or implied warranty that

these products will continue to have these

typical properties. ![]()

*Krytox® is a DuPont de Nemours trade name.